The tools and features shown in this tutorial are available in all Carveco products

Machining Reliefs

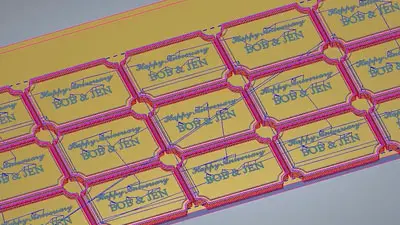

The Machine Relief Toolpath is designed to machine 3D Relief Artwork, or the entire surface of a composite relief, as quickly and efficiently as possible. You can also use the toolpath in a specific area of your model, defined by a selected vector.

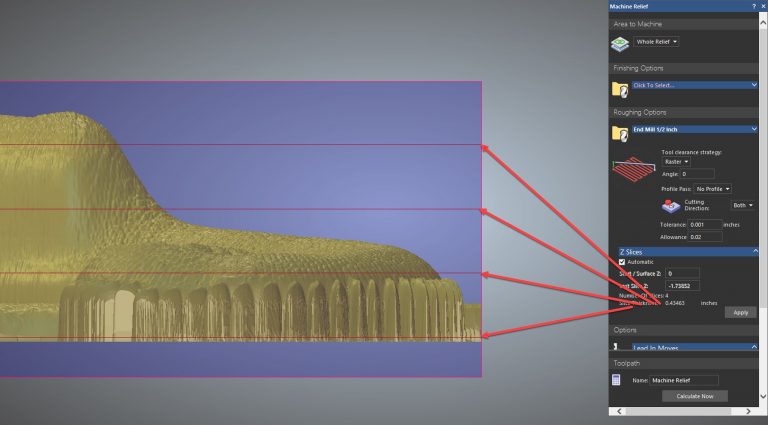

Z-Slicing

Essentially, Z-Slices refer to the way that Carveco analyses a 3D model at different depths to create a series of roughing passes around the 3D model surface.

Although the Automatic setting for Z-Slicing is most commonly used; Carveco lets you define the number of slices which will be used for the roughing operation of the Machine Relief toolpath.

3D Work Takes Time...

Creating and machining 3D work takes significantly longer than 2D work. And it's important to understand that it's not uncommon to spend several hours, or days, machining a detailed 3D piece to get a good quality outcome. There are many factors that you might want to consider that will help cut down production time, including using multiple tools, the size of your tools, toolpath tolerance, the capabilities of your machine tool, size of your piece or the amount of hand-finishing you're prepared to commit to the project. There's always a trade off between speed and quality when it comes to machining the final piece.